Best Automatic Granite Marble Kerbstone Production/Multi Blades Bridge Sawing Cutting Machine/Block Rock Limestone CNC Stone Edge Processing Cutter Suppliers

Description

Basic Info.

| Model NO. | Dafon Stone Cutter |

| Usage | Concrete Curb, Granite, Marble |

| Application | Machinery & Hardware, Construction, Mineral Industry, Stone Industry |

| Source Voltage | 380V |

| Automation | Automatic |

| Cutting Ability | High Speed |

| Control | PLC |

| Certification | API, CCC, SONCAP, GOST, ISO, CE |

| Machine Size | 7800*4500*6500mm |

| Water Consumption | 8.5m Cubic Meters Per Hour |

| Max Vertical Stroke | 1100mm |

| Weight | 12t |

| Beam Size | 500*600*7500mm |

| Blade Size | 1600-2500mm |

| Total Motor Power | 40-48kw |

| Main Motor Power | 37-45kw |

| Transport Package | Transportation in Containers |

| Specification | 7800*4500*6500mm |

| Trademark | DAFON |

| Origin | Quanzhou, China |

| HS Code | 8464109000 |

| Production Capacity | 200set/Year |

Packaging & Delivery

Package Size 780.00cm * 450.00cm * 650.00cm Package Gross Weight 12000.000kgProduct Description

| Product Description |

We provide customization product please contact our sales with detail requirement, we will manufacture machine accordingly

Special customization size:

Cross beam length: 6500-10500mm

Side beam length:4500-8000mm

| Machine Features |

Stone Block cutting machine Features:

The block cutter machine is mainly for granite and marble, it adopts multi-disc and PLC programmable control and man-machine interface, combined with a super-precision rotary encoder for slicing, uses frequency converter to control left-right feeding and adjusts the speed according to the stone material.stone block cutter adopts a hydraulic lifting system and forward-backward slicing adopts high-precision screw nut driving, automatic slicing, main spare parts adopt imported good-quality materials. The block can be placed on the ground directly, saving the cost of trolley and maintenance. It is especially suitable for cutting high-value granite and marble block because of high-efficiency cutting rate, high precision slicing, flatness, stability and easy operation.

Stone grinder machine uses CNC, configuration touch screen, configuration wireless remote control, configuration worm buckle joint, the first six motors can be 45 degrees - 90 degrees any electric adjustment angle, 45 degrees processing chamfering, adjust 70 degrees with water grinding piece processing large beveled edge, adjust to 90 degrees for roller processing a variety of shaped edge, No. 1, No. 2, No. 3 motor 4.5 kilowatts, No. 4, No. 5, No. 6 motor 3 kilowatts, No. 7 motor back cut 5.5 Kilowatt, after 6 motors stand put can be back and forth electric adjustment motor movement No. 8, No. 9 molding motor 4.5 kilowatts, No. 10, No. 11, No. 12, No. 13 fine polishing motor 3 kilowatts, chamfering motor No. 9, No. 10, No. 11, No. 12 3 kilowatts, for manual, automatic integrated machine, can be manually, automatic split operation, can be configured with a diameter of 18cm grinding wheel, the overall grinding wheel can be set a key lift, in and out of the guide Synchronous lifting, according to the different sizes of stone, thickness grinding a variety of flat stone size round edge, French edge, straight bottom edge 45 ºC chamfering, up and down chamfering with side polishing, flat polishing without silk line, up and down want R round side polishing, open stairs anti-slip with polishing with linear in one go, slot pulling light slotting pulling light (chicken beak edge) begonia angle, back cutting and other kinds of different line edge, rough grinding, fine grinding, polishing process in one go, the brightness after processing Higher than the brightness of the plate, polishing grinding wheel wear consumption, grinding wheel can be automatically compensated in the running process, without manual adjustment, advanced and reasonable structure, high precision, fast efficiency, easy to operate, simple maintenance, in the grinding process can adjust the feed speed and carry out the amount, the maximum processing 5m / min, the normal use of machinery equivalent to the normal stone processing 15 people workload, and to eliminate the emergence of workers when processing process Defects.

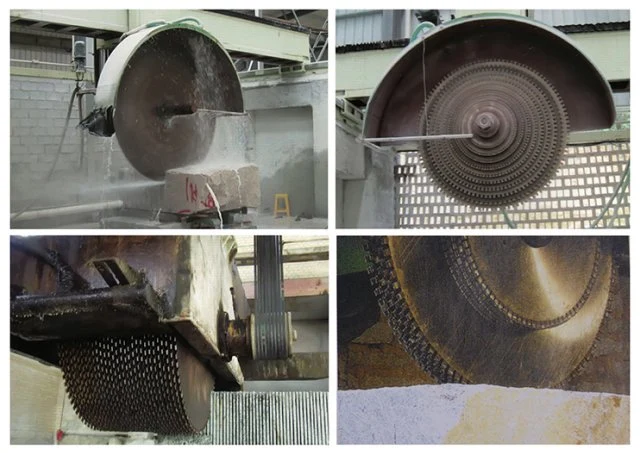

Kerb stone cutting machineThis machine line is mainly for cutting slab width above 50mm, the machine cut with 10-14pcs of blade at the same time which will dramatically increase cutting speed and overal output, daily capacity can reach 30-35m³/24h.The machine is widely used for kerbstone, roadside stone, cobblestone and tombstone etc.Machine part:The machine line included one slicing machine(DF1200-12S) and one edge cutting machine(DF1200-1S), worker load thick slab to the slicing machine with a crane, after slicing machine finish cutting, the roller on worktable hydraulically lift up and transfer the stone to the next edge cutting machine.The edge cutting machine has hydraulic pushers to push all the stone with blade gap tight and together to ensure a precise cutting. After that, the cutting process is finished and ready for packaging.

Electrical part:

Machine use Mitsubishi PLC control system, SIEMENS water proof button, Omron relays etc, the machine is equipped with remote control, worker can both use the controlling cabin or remote control during operation.

Advantage:

- Segments saving: machine use multi-blade cut at the same time, every down cut is about 3-5mm(depends on stone and segment), which save segments consuming.

- Labor saving: the entire machine line only need one worker to attend to it, machine adopts rollers to transfer stone and sensors for automatic stop and operation.

- Workshop space saving: compared to other cutting methods, the machine need only 12*5m space when producing same capacity.

1. no cement foundation needed, easy installation and shipment(40'' HQ).2. the main shaft adopts high frequency modulation treatment, which will be more durable and wear-resisting. 3. kerb stone cutter uses main spindle and a vice spindle to seal all saw blades together which can ensure the machine stable while cutting hard granite.4. it uses a simple program of movement on the controlling box, easy for setting, operating, and maintaining.5. Kerb Stone Cutting Machine adopts two hydraulic pillars(a set of hydraulic systems) on both sides of the machine to ensure the strength of cutting spindle lifting up and down.6. Unlike traditional stone cutting, it dramatically increases productivity and reduces labor cost and power consumption and it consumes less diamond segment per cubic meter of production compared to the traditional cutting machine.7. Cast iron is adopted in the main frame of the machine to make the machine more stable with less chance of vibration under the operating condition.

| About Us |

We are a CE certificated manufacturing factory, professional stone machine factory that integrates design, manufacture, and trading as one. We mainly produce a multiblade stone cutting machine(especially for curbstone/kerbstone/cobblestone etc), infrared edge cutting machine, automatic line polishing machine, full automatic edge cutting machine line, multiblade stone block cutter, quarry mining machine and all sorts of stone cutting and processing machines. We also bring in new technology on manufacturing environment-friendly equipment, such as a waste water recycling system, stone dust vacuum cleaner, etc.Based on industrial cluster advantage, we offer one-stop stone cutting product solutions for free to our customers including guidance for mine planning, technical consultant, technical output, equipment and tools purchase, guidance for factory construction, etc.

| Certification |

| Our Exhibition |

| Machine Loading |

| After-Sales Service |

We provide skilled and rich experience technicians for installation and after-sale service.

| Pre-Sales Service * Inquiry and consulting support. * Configure the best machine line according to customer condition * View our Factory. | After-Sales Service * Training how to install the machine, training how to use the machine. * Engineers available to service machinery overseas. * Lifetime technology maintenance in free and spare parts supply. Related Products |

| FAQ |

Q: When can you ship my order?

A: Normally 15-20days after advanced payment is received. The exact delivery date will be advised after order is confirmed. We will try our best to deliver soonest, if you need them urgently.

Q: How long is the warranty period for machine?

A: one year !

Q: How do I install and operate the machine, after receiving it?

A: For simple machine, we will provide sufficient installation, operation and maintenance instruction and videos, which will make the whole thing as simple as possible for users. For high-tech machine, our engineers can fly abroad to help you install & debug the machine, and teach you how to operate and maintain the machine properly in the future.

Q: Are you manufacturer or trading company?

A: We are manufacturer that has our own factory, technical Dept., marketing and after sale service teams.

Q: What is your advantage?

A: Firstly we are manufacturer, you could get best price without paying any commission. Secondly, we provide advisory machinery, debugging, maintenance and fault handling package of services. Thirdly, we offer customized overall solutions and one stop service. Both of our machine and diamond tools are excellent. Fourthly, we give you technology support on not only machine, but also diamond tools. Finally, better and lower cost after-sale service could be provided thanks to our worldwide network.

Prev: Hot Sale China Stone Multi Blade Block Cutter for Granite Marble (DQ2200/2500/2800)

Next: Interchangeable Tungsten Carbide Bush Hammer Sawtooth Cutter for Concrete and Marble Grinding

Our Contact